52

countries

where the company's products

are exported

are exported

2

million tons

sales of pipe

products per year

products per year

5

Top

world largest producers

of tubular products

of tubular products

3

billion $

of investments in production

in 2005-2018

in 2005-2018

ChelPipe Group is a major player in the Russian metallurgical cluster and one of the largest domestic producers of tubular products.

Innovation cases

Big Data

Application of new mathematical models based on Big Data technologies in production.

Outcome:

new digital methods have been introduced into the processes to optimize the loading of the charge into the electric arc furnace of "Iron Ozone 32" shop.

Laser welding

Technical adaptation of innovative laser welding technology in the production of large diameter pipes.

Outcome:

a laser pipe welding mill was put into operation, a pilot batch of pipes was manufactured, technical specifications were signed with a partner for the manufacture and supply of pipes using laser- welding.

Steelmaker assistant module

Development and implementation of the program module "Steelworker Assistant", which gives advice for optimal fusing.

Outcome:

a reduction in the ferromaterials consumption achieved as well as an increase in the productivity of fusing.

In order to maintain the pace of innovative development Chelpipe Group launches the Corporate Accelerator - a program for the fast-track development of technological startup for the purpose of the following implementation into Chelpipe’s facilities or potential investments.

Benefits for participants

PILOT

Paid pilot project with Chelpipe Group.

BUSINESS CUSTOMER

A specific customer for each project from one of the Chelpipe Group’s units.

ACCELERATION

Individual program of industrial acceleration.

EXPERTISE

Support from leaders in the metallurgical industry.

Find a customer of your technology in the Chelpipe Group

Program streams

We invite projects aimed at developing of innovative products, new materials or technologies applicable in the pipe industry to take part in the Accelerator.

Projects’ proposed solutions should correspond to one of the streams below.

New innovative products relevant to the pipe industry

New Products and Materials

New pipes and materials

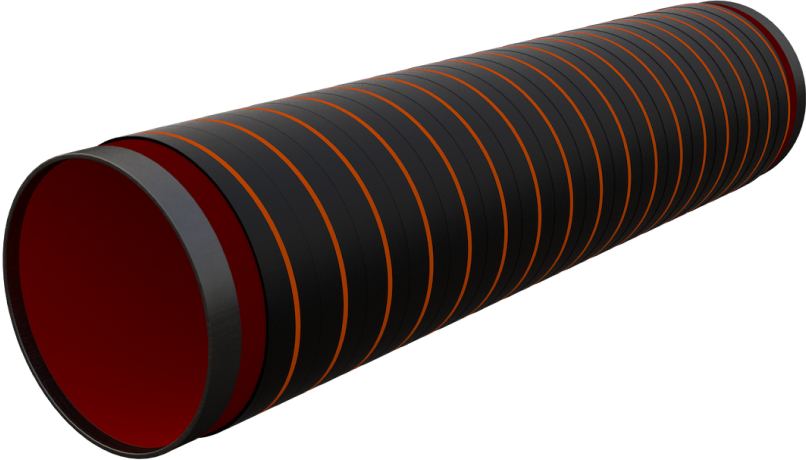

- New types of welded and seamless pipes

- New steel grades for threaded and oil and gas pipelines with high resistance for oil environments containing hydrogen sulfide and carbon dioxide

New complementary products for pipes (parts, etc.):

- New types of pipe fittings

- New types of stamped parts

- New types of pipe joints for wells to replace traditional threaded joints

New manufacturing technologies

Pipe Production Technologies:

- New technologies for the production of cold-deformed and hot-deformed pipes;

- New technologies for the production of large diameter pipes;

- Hardening technology for threaded pipe ends

- New grease technology for hot rolling tubes;

- New grease technology for hot rolling tubes;

- New ways of threading (molding a threaded part).

- New technologies for connecting oil and gas pipes in the field

- Methods of aligning pipe-cutting and coupling-cutting machines for technological accuracy and assessing the technical condition of nodes

Technologies complementary to the production of pipes (coating, cleaning, etc.)

- New technologies for applying external and internal pipe coatings;

- New thread coating technologies;

- Technologies for cleaning the inner surface of seamless pipes from scale.

- Technologies for cleaning (matting) pipe threads (nipple and coupling).

- Methods for removing galvanic copper plating on couplings.

New technologies for monitoring pipe products

Product traceability systems during production and life cycle (RFID tags, etc.)

Methods for marking semi-finished and finished products with information reading systems in the production of hot-formed and cold-formed seamless pipes.

Smart pipe technologies for remote monitoring of trunk (LDP) and field (NGP) pipelines (including pipe physical condition monitoring systems (sensitive sensors), data processing and transmission systems, Industrial Internet of Things).

Smart pipe technology for remote monitoring of tubing tubing (including pipe physical condition monitoring systems (sensitive sensors), data processing and transmission systems, Industrial Internet of Things).

Development of innovative substitute products for traditional steel pipes or pipe coatings

Products substitutes for steel pipes: reinforced polymer-composite pipes based on polymer matrices (including thermoplastic) and modern fillers (fibers, modifiers) manufactured by extrusion, pultrusion and winding

A new type of coating that improves the consumer characteristics of pipes.

New coatings for threaded joints

New threaded greases.

New technologies and devices for protecting the threaded ends of pipes for the period of transportation and storage at the warehouse (up to 24 months minimum).

New technologies for protecting the outer and inner surfaces of pipes from atmospheric corrosion, including in a marine climate, for the period of transportation and storage at the warehouse (up to 24 months minimum).

Technologies and solutions for integration of smart pipe systems, power and control electric cables, etc. into reinforced polymer-composite pipes

Machine vision systems for existing production in the areas

Production control

Cold and hot-deformed seamless pipes;

Large diameter electric welded pipes;

Contactless measurements:

Geometric dimensions of the pipe;

Geometric dimensions of the thread of pipes and couplings;

Visual control of the presence and correctness of labeling.

Ecological production ("white metallurgy")

Use of energy-efficient equipment / energy-efficient technologies in pipe production

Technologies for the processing of waste pipes and steelmaking

Other

Project stage

Prototype and higher. An experimental prototype is manufactured and tested.

Economic effect

Project implementation should bring measurable economic effect.

Implementation possibility

Implementation should be possible into the current production facilities of Chelpipe Group.

Project requirements

REQUEST RECOMMENDED PITCH DECK TEMPLATE

Event calendar

Application submission

15 January – 31 March 2020

#GENSTalks in Moscow

February 20th 2020

Projects expertise

1 April – 15 May 2020

Bootcamp

beginning of June 2020

Acceleration program

June - November 2020

Demo Day

27 November 2020

Experts

Gizatullin

Anton Bilguvarovich

Anton Bilguvarovich

Head of New Products Division

Ilyina

Maria Vadimovna

Maria Vadimovna

Leading Project Management Specialist

Kormiltsev

Alexey Vladimirovich

Alexey Vladimirovich

Head of the project implementation department for new types of industrial pipes

Krikotin

Victor Vladimirovich

Victor Vladimirovich

Project Manager "Organization of the production of polymer-composite pipes"

Taved

Anastasia Igorevna

Anastasia Igorevna

Leading Research Engineer

Guseva

Marina Alexandrovna

Marina Alexandrovna

Head of New Pipe Coating Group

Lunev

Alexander Alekseevich

Alexander Alekseevich

Head of the Center for Mathematical Modeling and Artificial Intelligence

Alexandrov

Sergey Vladimirovich

Sergey Vladimirovich

Head of Project Implementation Department "Integrated Well Support"

Devyaterikova

Natalya Anatolevna

Natalya Anatolevna

Leading Research Engineer

Makovetsky

Alexander Nikolaevich

Alexander Nikolaevich

Head of Project Management Department

Bykov

Arkady Petrovich

Arkady Petrovich

Chief Specialist (Premium Service)

Shander

Sergey Viktorovich

Sergey Viktorovich

Head of LDP Project Implementation Department

Vasilyeva

Elena Vladislavovna

Elena Vladislavovna

Head of Internal Communications

Babinets

Anna Vladimirovna

Anna Vladimirovna

Head of Human Resources

Bragina

Alla Alekseevna

Alla Alekseevna

Leading Specialist

Cherepanova

Tatyana Alexandrovna

Tatyana Alexandrovna

Head of Press Service

Sokolov

Sergey Alexandrovich

Sergey Alexandrovich

Head of Economic Security

Larionova

Elena Alexandrovna

Elena Alexandrovna

Lead Counsel

Lyamina

Marina Mikhailovna

Marina Mikhailovna

Deputy CEO of operational excellence

Leontiev

Ekaterina Pavlovna

Ekaterina Pavlovna

UZU Manager

Snegirev

Roman

Roman

Head of digital marketing and e-commerce department

News

FAQ

Do I have to share confidential information?

- No. Only enter the information in your application that you can share without an NDA (Non-Disclosure Agreement).

I represent 2 projects. Can I submit multiple applications?

- Yes. The number of applications is unlimited, but a separate profile must be registered for each project.

Can I meet you in person and receive feedback about my project?

Occasionally, the accelerator team takes part in partner events and organizes our own #GENSTalks, where you can approach the team members for a consultation. Please follow us on our website and in social networks.

Contacts

Moscow , Skolkovo Innovation Center, ul. Nobel, 1

Phone:

Fax:

—

petrova.es@rvc.ru —

Ekaterina Petrova, Director of corporate accelerator

—

lazarchuk.ka@rvc.ru —

Kirill Lazarchuk, Project Manager

—

martynova.iv@rvc.ru —

Irina Martynova, Head of corporate direction

—

admin@generation-startup.ru —

Technical support

Join Chelpipe accelerator